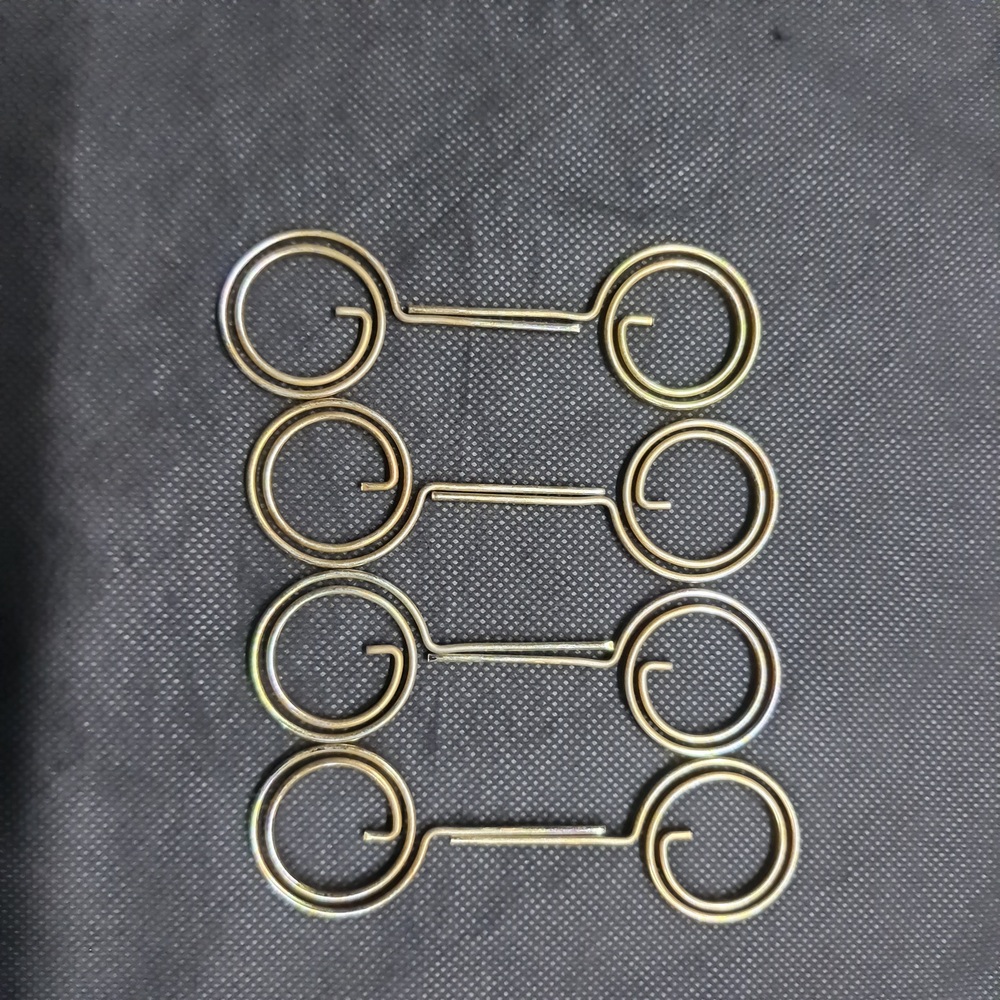

Door Handle Spring

Door Handle Spring Specification

- Capacity

- 10000 Pcs/hr

- Style

- Spiral

- Usage

- DOOR HANDLE

- Load Type

- Torsion

- Material

- Carbon Steel

- Size

- 1.5*1.5

- Height

- 30 Millimeter (mm)

- Wire Diameter

- 1.5 Millimeter (mm)

- Product Type

- TORSION SPRING

- Weight

- 150 Grams (g)

- Surface Finish

- ZINK

- Color

- YELLOW ZINK

- Length

- 60 Millimeter (mm)

Door Handle Spring Trade Information

- Minimum Order Quantity

- 6 Pieces

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Delivery Point (DP), Telegraphic Transfer (T/T)

- Supply Ability

- 100000 Pieces Per Month

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- AS PER NEED

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO 9001:2015

About Door Handle Spring

Upgrade your door hardware with this versatile door handle spring that ensures smooth operation and reliable performance. This 29mm round spring features 2.5 turns of precision-engineered zinc-plated steel Grade II construction, offering excellent durability and consistent tension. The universal fit design makes it compatible with a wide range of door handle mechanisms. The spring's asymmetric ends - a 28mm long leg and a 7mm short leg - are specifically designed for optimal installation and functionality. The round end provides stable anchoring within the handle assembly. Perfect for residential and commercial applications, this spring maintains proper handle return action and helps prevent handle drooping. The zinc plating provides enhanced corrosion resistance for extended service life. Ideal for replacement or repair projects, this spring delivers professional-grade quality and reliable performance for your door handle mechanisms.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Type And Special Purpose Spring Category

Cable Protected Spring

Price 10 INR / Foot

Minimum Order Quantity : 50 Feet

Material : Stainless Steel

Wire Diameter : 0.5 10 Millimeter (mm)

Usage : Machine, Fixer, Switch, COVER, ELECTRIC MACHINE, MOTOR, HEAVY DUTY SPRING

Style : Spiral

Spiral Spring

Price 25 INR / Piece

Minimum Order Quantity : 25 Pieces

Material : Stainless Steel

Wire Diameter : 0.5 10 Millimeter (mm)

Usage : Machine, Project,

Style : Spiral

Barrel Spring

Price 125 INR / Piece

Minimum Order Quantity : 20 Pieces

Material : Other

Wire Diameter : 0.5 10 Millimeter (mm)

Usage : Machine, Project,

Style : Coil

Garter Spring

Price 0.20 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Other

Wire Diameter : 0.2 5 Millimeter (mm)

Usage : Oil Seal

Style : Cylinder

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese